Slip resistance at the New York Times printing press

Slip resistant steel plates increasing worker efficiency at the New York Times printing facility

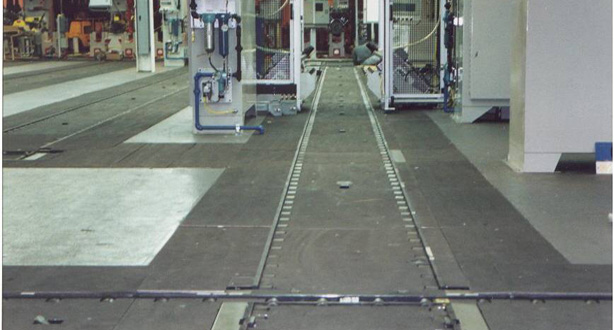

The Ford Livonia Transmission Plant opened in 1952 and sits on 182 acres, making it the largest transmission plant in North America. They have produced more than 1 million automatic transmissions, which amounts to more than 3,700 a day. They also produce thousands of transmission components a year, including gear sets and torque converters. Due to all the metalworking operations required in making transmissions, the units can drip fluids as they progress along the conveyor line. Since 1989, SLIPNOT has been utilized in various Ford plants such as the engine, stamping and assembly plants. The Livonia Transmission Plant was looking for a non slip product for around the conveyor lines, due to oils.

SLIPNOT recommended Grade 2 steel plates to a conveyor manufacturing company who assembled them to be used over the concrete aprons around the assembly line, as well as conveyor top covers. The plates were pre-cut, allowing for the rollers on the conveyors to emerge through. Once these plates were installed, the transmission fluid, cutting fluids and machine oils were no longer an issue for the assembly workers. They felt confident around the conveyors, knowing they had slip resistance under their feet.

The Ford Livonia Transmission Plant replaced their slippery bare diamond plate with SLIPNOT's slip resistant, long lasting steel floor plates. The employees found confidence knowing that injuries were being prevented due to the file hard non slip surface which will never flake or wear smooth.

Slip resistant steel plates increasing worker efficiency at the New York Times printing facility

High traction steel plate creates safety on new and existing work platforms.

Non slip stainless steel plates enhance the safety of Lift-A-Loft scissor lifts.

The SLIPNOT team is efficient, expert and focused on providing you with the right safety solution. Please take a minute to complete this form to request a quote or sample. One of our safety professionals will be in touch to help guide you in making the right choice.