Floor Plate

SLIPNOT slip resistant plates are the perfect solution for non-slip flooring applications in manufacturing facilities, food processing plants, or even commercial buildings.

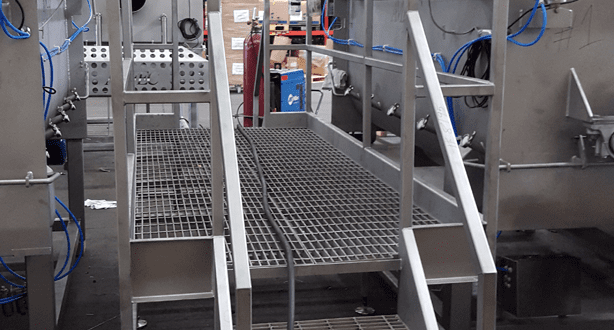

SLIPNOT slip resistant grating is an excellent selection for non-slip flooring applications on mezzanines, platforms, catwalks, or other wet or potentially oily environments. Any flooring application that would require exceptional drainage, additional light, or remarkable air flow can still achieve the noteworthy performance of SLIPNOT’s unique traction maximizing technologies.

| 2’x20’ | 2’x24’ |

| 3’x20’ | 3’x24’ |

| 19-4 | 19/16” Spacing (1” Open) | Standard Industrial |

| 15-4 | 15/16” Spacing (3/4” Open) | Standard Industrial |

| 11-4 | 11/16” Spacing (1/2” Open) | ADA |

| 7-4 | 7/16” Spacing (1/4” Open) | ADA |

Consider that the grating may bow from the heat of the SLIPNOT process and adequate fastening is advised.

SLIPNOT customers have the option of sending their own material to take advantage of our proprietary anti-slip application technologies. Take advantage of our speed and agility to get your finished product as quickly as possible.

As experts in our field, SLIPNOT is able to customize a finished product to the most demanding specifications. From modified finishes and paints to powder coating and added logos, our talented Operations team can produce products that are uniquely your own.

SLIPNOT slip resistant plates are the perfect solution for non-slip flooring applications in manufacturing facilities, food processing plants, or even commercial buildings.

SLIPNOT slip resistant technologies add an additional level of safety to ladder rungs, ladder rung covers, handrails, and other tube structures.

SLIPNOT slip resistant planks and covers provide anti-slip solutions for decking, platforms, trenches, expansion joints, basin drains, sanitary drains, utility vaults, manholes and so much more.

Foot Hold by SLIPNOT is a powerful water-based cleaner and degreaser formulated for use with SLIPNOT products and in all areas of your facility where you have slip and fall hazards.

Steel grating ramp increases safety on stamping press access platforms

Non-slip stainless steel grating and treads for raised platform at SugarCreek Packing Plant

Kent Quality Foods – Purchaser