ANTI-SLIP

Grating Coating

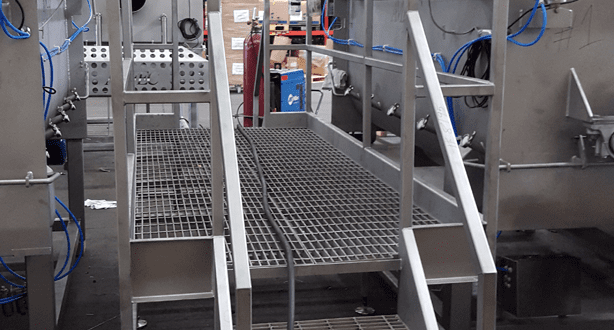

SLIPNOT® slip-resistant grating is an excellent selection for non-slip flooring applications on mezzanines, platforms, catwalks, or other wet or potentially oily elevated environments. Any flooring application that would require exceptional drainage, additional light, or remarkable air flow can still achieve the noteworthy performance of SLIPNOT®‘s unique traction-maximizing grating coating.

SLIPNOT® can also supply a variety of grating and screen products from Hendrick Architectural. Whether your application is interior or exterior, these products are ideal for trench grating, stairs, entrance floor grilles, and more!

PRODUCT DETAILS

SLIPNOT® Slip-Resistant Grating

Our SLIPNOT® grating coating delivers high-friction surfaces for optimal safety performance. We apply non-slip coating at our headquarters in Michigan for new projects and retrofitting industrial grating structures. Our safety grating is a non-skid alternative. We specialize in heavy-duty smooth bar grating for catwalks, mezzanines, and raised platforms. SLIPNOT® coating does not adhere to serrated grating. Grating options are corrosion-resistant and available in custom and stock sizes.

- Registered by NSF International for application food processing facilities

- Available in multiple design options for heavy duty applicaton

- Available Hendrick Architectural stock products

- Entrance grilles, stair components, tree grating, trench grating, drain covers, fountain grating, ventilation grilles, and signage

- Allows for liquid, light, and air passage

- Easy installation for active project sites

- Retrofitted into existing industrial structures

- Exceeds anti-slip standards and recommended Coefficient of Friction (CoF) guidelines throughout the product life

- Exceeds OSHA, ADA, and ANSI requirements

- Heavy-duty grating withstands tough environments

SPECFICATIONS

High-Friction Grating Options

- Stock Sizes: (Maximum 36” panel width)

2’x20’ 2’x24’ 3’x20’ 3’x24’ - Bearing Bar Height: 3/4″ to 2-1/2″ tall (in 1/4″ increments)

- Bearing Bar Thickness: 3/16″ (typical) and 1/4″ upon request

- Spacing Options (Ctr – Ctr spacing between bars – open area listed for 3/16” thickness)

19-4 19/16” Spacing (1” Open) Standard Industrial 15-4 15/16” Spacing (3/4” Open) Standard Industrial 11-4 11/16” Spacing (1/2” Open) ADA 7-4 7/16” Spacing (1/4” Open) ADA - 2” cross bars, heavy duty spacing, trim or load banding for rigidity available upon request

- Style Availability by alloy:

- Steel: Light duty welded (typical), heavy duty welded, pressed or swaged locked

- Stainless Steel: Swaged locked (typical), light duty welded (limited availability)

- Aluminum: Swaged locked (typical), dove tailed, swaged locked I-Bar or flush top

- Grip Levels: Fine (Grade 1), Medium (Grade 2), or Coarse (Grade 3, Steel Only).

- Standard finishes include Mill, Painted, Galvanized Steel, and Powder Coated.

- Powder Coating is available in a variety of colors—discuss options with a Salesperson.

- Paint is available in black, gray, red, and safety yellow.

- Hendrick Architectural Profile Bar is available.

INSTALLATION METHODS

Non-Slip Grating Application

- Saddle Clip, Anchor Block, or Countersunk Land (available from grating manufacturer)

- Weld to existing metal structures or framing

- Free set into frame

Consider that the grating may bow from the heat of the SLIPNOT® process, adequate fastening is advised.

CUSTOM

Safety Grating Coating

As experts in safe industrial grating, SLIPNOT® is able to customize a finished product to the most demanding specifications. From modified finishes and paints to powder coating and added logos, we can produce products that are uniquely your own.

Our Team Can Help:

- Identify the alloy appropriate for your operational environment

- Select the surface grade for the finished plate, Grade 1 (fine), Grade 2 (medium), or Grade 3 (Coarse, Steel Only)

- Provide preferred installation method

- Provide a drawing of the finished good or work with SLIPNOT®’s outstanding Engineering team to develop a drawing from your input

- Specify any unique finishing requirements

DOWNLOADS

Slip-Resistant Grating Product Details

STOCK MATERIALS

Hendrick Architectural Products

Click on any of the links below to learn more about the products you can get from Hendrick Architectural with SLIPNOT®.

PROUDLY CERTIFIED BY

Customers Also Purchased

Maximizing Traction For Our Customers

Slip resistant steel grates increase safety on Nissan enter & exit ramps

Steel grating ramp increases safety on stamping press access platforms

Anti-Slip Stainless Steel Gratings and Treads for Platform in SugarCreek Packing Plant

Non-slip stainless steel grating and treads for raised platform at SugarCreek Packing Plant

Great product and service. Helps achieve safety goals in a big way.

Kent Quality Foods – Purchaser

Download Our Product Catalog

"*" indicates required fields